Sludge dewatering in municipal or industrial waste water treatment is classified as complex. Not only the composition of the sludge, but also the economic and technical boundary conditions of the plant vary greatly. The optimal solution can only be reached by analysing the overall situation. Minimising dewatering costs while simultaneously reducing residue quantities are also clearly defined objectives for users. Accordingly, a stationary filter plant can only be used with a low degree of utilisation. Cost-intensive investments are therefore often offset by moderate capacity utilisation.

ECONOMIC APPLICATION MOBILE FILTER TECHNOLOGY

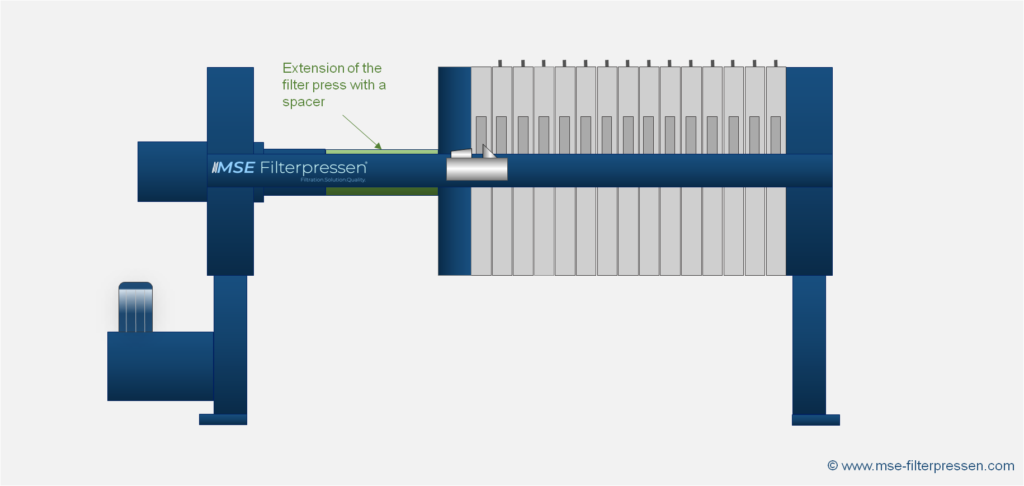

The more specific a process-technical plant, the higher the associated investment costs. Especially in industrial waste water treatment plants, this fact inevitably leads to an economic conflict situation. Efficient and technically superior dewatering systems such as filter presses are characterised by relatively high investment costs and low plant utilisation. In addition to the semi-mobile filter presses, the mobile filter press plant is the answer to the question of an economical yet self-sufficient filtration method. Practical experience shows that the ratio of investment costs compared to a short to medium-term acquisition of a mobile filter press can be in the range of 1:3 to 1:15. Similar conditions can also be observed with regard to operating costs.

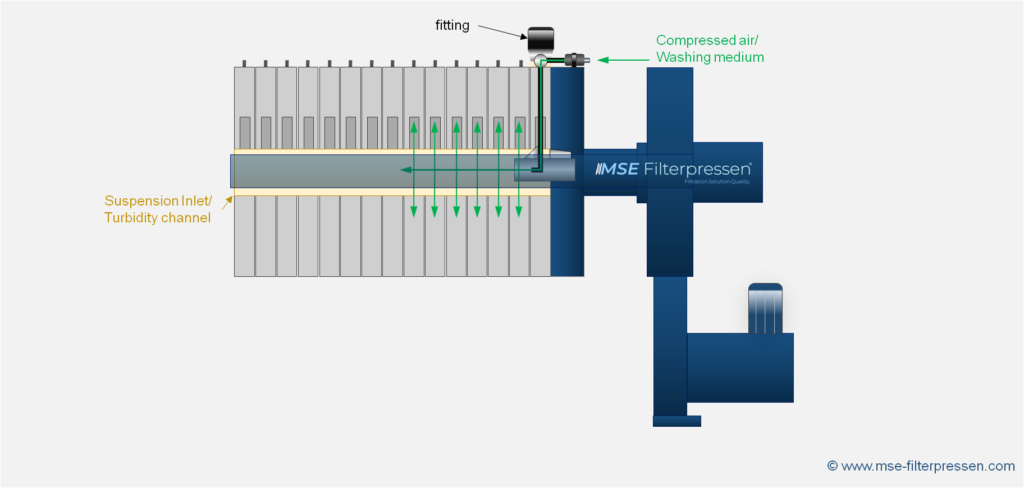

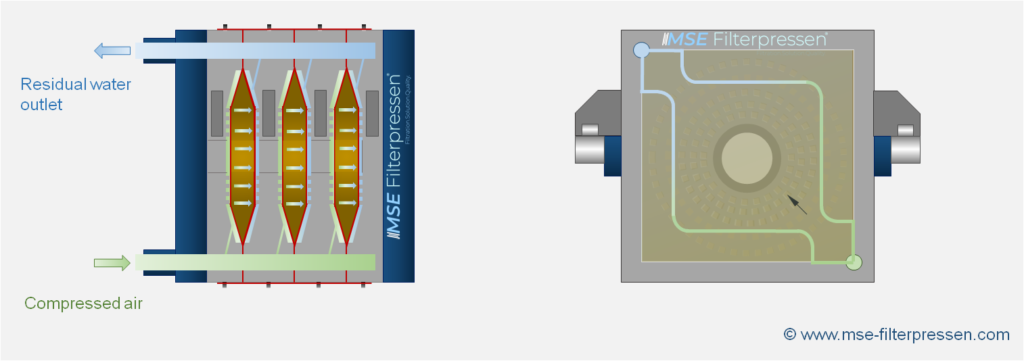

MSE mobile filter presses are fully equipped and immediately ready for operation after connection of the sludge, water and power supply. In this way, the best possible result can be achieved for every task. MSE Filterpressen® also helps you with the planning and assembly of your individual plant. At this point, mobile filter presses are particularly suitable for dewatering sludge from several plants at regular intervals or for compensating capacity peaks and bottlenecks. The fact that mobile filter presses are not subject to approval obligation and are therefore quickly and unbureaucratically available is particularly interesting.